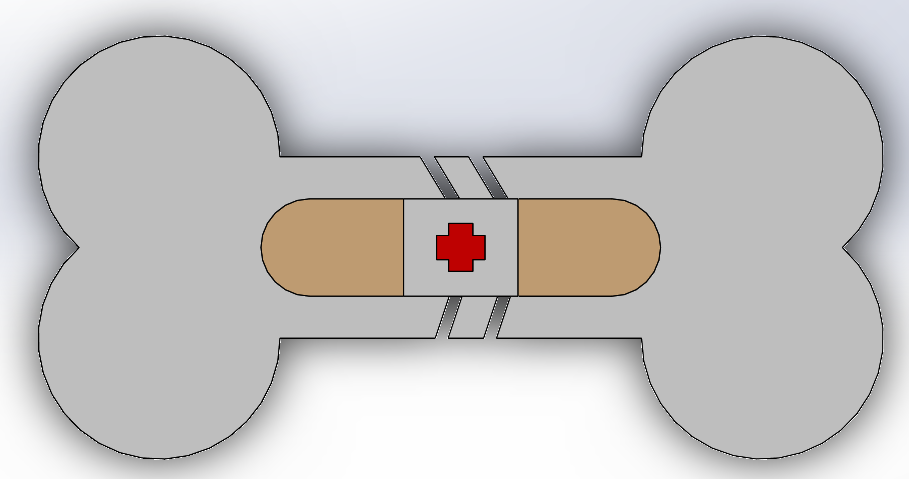

Our purpose is to determine if increasing the frictional force between the bone and the plate reduces failure on the screws

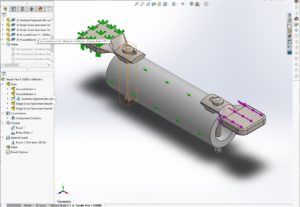

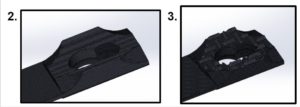

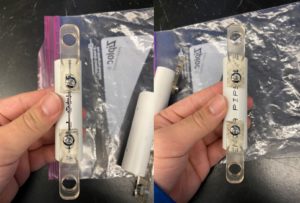

For preliminary data and machine calibration, we decided to simplify the device so we can look at one hole per plate (schematic on the left). Using this design, we are comparing smooth plates (2) against textured plates (3) in tensile and fatigue conditions.

Results

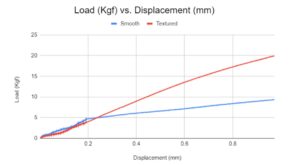

Smooth Textured

On truncated plastic samples, the textured sample performed better than the smooth sample

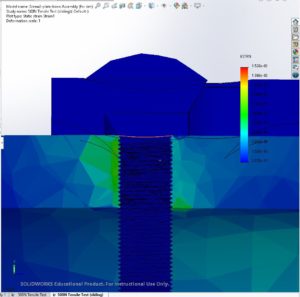

To better understand how failure occurs in the screw, a Finite Element Analysis (FEA) was performed. As seen in the image below, areas shown as green are regions of highest stress. This is where failure is most likely to occur. A solution that reduces failure of the screws should also reduce the stress level in these high-stress regions.